When to employ angled screw channels for implant restorations?

The problem is that often implants are placed at angles that can make it difficult to fabricate conventional screw retained implant restorations because the screw hole would come out in a undesirable place ( on the buccal, lingual or proximal surface). Five years ago our best option for these implants was to fabricate either a custom implant abutment and a cement retained crown or a multistaged implant restoration( more complicated and expensive).

In the last several years laboratories are recommending digitally designed angled screw channel connections that allow screw retained crowns for single unit implant restorations even when the screw axis is off by as much as 30 degrees. These employ special drivers that work with the screws that are used with the angled screw channels. A number of manufacturers have been manufacturing these and often a dentist will collaborate with his lab to determine which to use. Unfortunately, none of these were designed to be used for the sort of metal frameworks many dentists prefer for splinted implant restorations, at least until the last year.

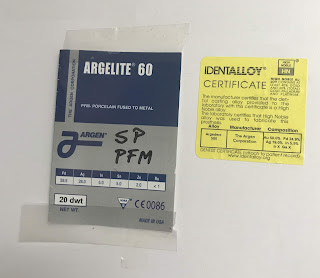

Last Thursday I attended a Spear Study club and watched a presentation of Rhyno Kaye who is employed by Town and Country and he explained that now there is an angled screw channel that can be utilized with pfm bridge work that employs a chromium cobalt substructure. Once an accurate master model can be tested using a verification jig, the verified the model can be scanned and a framework with the proper angled screw channels can be digitally designed and milled. This framework can have porcelain baked on and a splinted bridge can be fabricated even if some of the implants are angled in non ideal orientations. I expect that as time goes on this technology will continue to improve and more labs will offer it for their clients to use.

Given the speed of innovation in the world and in dentistry, continuing study and education is needed in order to provide our patients with state of the art dental care. I have chosen to participate with 4 dental study clubs and teach at NYU College of dentistry part time. Even though I have been in practice for over 40 years, hardly a week goes by that I do not learn something new and this helps keep dentistry interesting . Most days, I look forward to going to work and putting new things I've learned into everyday practice.

from Ask Dr. Spindel - http://lspindelnycdds.blogspot.com/2021/04/when-to-employ-angled-screw-channels.html - http://lspindelnycdds.blogspot.com/

Comments

Post a Comment